Printers

Retransfer Card Printers – FAQ

What is retransfer printing?

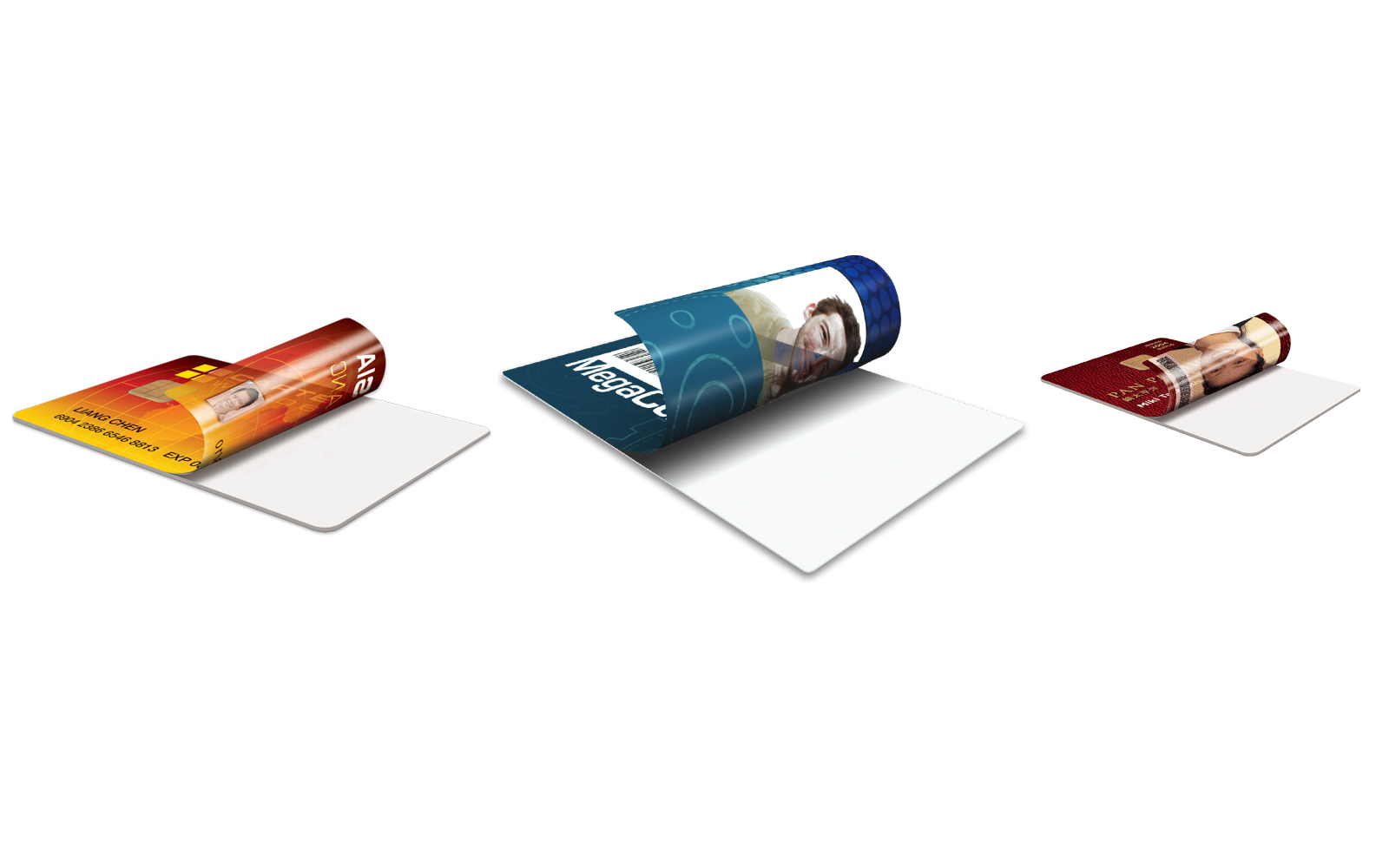

Retransfer technology uses a two-step process called reverse thermal transfer. The retransfer process prints a high-resolution image in reverse directly onto a clear receiving layer carried by a flexible intermediate skin. The dye sublimation process prints the image to the film and then uses heat and pressure to thermally transfer the image and the entire image-receiving intermediate film onto the card surface. The printed image resides underneath the clear image-receiving layer, inside the card.

Retransfer delivers high print quality, the ability to print on uneven card surfaces such as smart cards, and on non-PVC cards, for a more durable and abrasion-resistant card that lasts longer than traditional materials.

Superior image quality

Separates the image creation step from the process of applying the image to the card, relieving many of the constraints of direct-to-card (DTC) printing, and optimises the dye for print quality – regardless of the card material.

Greater flexibility

Over-the-edge printing enables true edge-to-edge images, giving users access to the entire card surface. Retransfer process is relatively insensitive to card materials allowing for high quality images on a wide variety of card types such as biodegradable cards enabling “green” initiatives.

Improved security

The retransfer film provides fraud protection since the film easily shows tamper evidence.

Retransfer technology allows the use of transfer films with holographic images and laminates with a multitude of security features such as holographic images, optical variable ink, and morphing.

Lower printhead costs

Printhead lifespan improves dramatically because retransfer printers print on soft retransfer film panes and not on rigid card substrates as with traditional DTC printers resulting in a reduction in overhead for spare printheads, lower maintenance workload, and improved ROI.

How does retransfer printing differ from DTC printing?

Direct to card printing uses a traditional dye sublimation process and printhead to transfer the image through a dye ribbon directly onto the card surface. Retransfer uses the same dye sublimation process but prints the image in reverse onto a clear intermediate film which is then thermally transferred directly onto the card using heat and pressure.

Zebra ZXP Series 9 Retransfer Card Printer

What is the Zebra ZXP Series 9 Retransfer Card Printer?

The Zebra ZXP Series 9 printer is based on leading-edge hardware and software technology that meets demanding enterprise needs for high-perfomance, photo-quality card printing. Retransfer technology is the optimal on-demand printing solution for meeting the stringent image quality and encoding standards that advanced card applications require. Retransfer printing is ideal for a broad range of applications such as:

- High-security credentials and identification cards

- Loyalty, membership and retail cards

- Financial cards with magnetic or smart card encoding

- Many other applications

Can the Zebra ZXP Series 9 printer print on both sides of the card?

Yes, the Zebra ZXP Series 9 dual-sided card printer prints using a patent-pending process that applies the printed transfer film to both sides of a card at the same time. Other retransfer printers are limited to applying the transfer film to the card one side at a time. This simultaneous front/back transfer process enables breakthrough printing speeds and throughput.

Since the Zebra ZXP Series 9 printer applies the transfer film to both sides of the card simultaneously, will I lose a transfer panel if I only print on one side of the card?

No, the ZXP Series 8 card printer is designed to automatically wind back one panel of transfer film when you print only on one side of a card to minimise the number of unused transfer film panels per roll.

Can I print colour on both sides of the card?

Yes, the ZXP Series 9 dual-sided configuration will print in colour on both sides of the card simultaneously. The ZXP Series 9 single-sided card printer prints on one side of the card only.

Does the ZXP Series 9 print edge-to-edge?

Yes, the ZXP Series 9 printer is specifically designed to print and image in a slightly oversized form fact or than that of the card surface resulting in a full “over-the-edge” effect. This produces a sleek, photo-like appearance that is very different from the traditional ID card. If your printer has the laminator, it is highly recommended that any printed security elements be located under the laminate patch.

What are the standard features of the ZXP Series 9 printer?

Standard features for the ZXP Series 9 printer include:

- USB connectivity and Ethernet-ready (available via firmware upgrade)

- Single and dual-sided printing

- Print speeds (max): 190 cph single-sided, 170 cph dual-sided

- Single-card feed capability

- 150 card capacity feeder (30 mil)

- 15 card reject hopper (30 mil)

- 100 card output hopper (30 mil)

- Auto calibration of media

- 64 MB memory

- 21-character, 6-line LCD operator display

- 304 dpi (12.0 dots/mm) print resolution

What options are available on the ZXP Series 9 printer?

Options for the ZXP Series 9 card printer at launch will include:

- ISO HiCo/LoCo magnetic stripe encoding

- MIFARE contactless and contact encoder combo

- Contact station for third party contact encoders

- Lockable enclosure/card feeder

Options available in future releases include:

- Single- and dual-sided laminator

- UHF Gen 2 RFID encoding

- iClass contactless and contact encoder combo

- Prox reader and contact encoder combo

- 802.1 b/g and 1 GB Ethernet connectivity

- Barcode scanner

- Built-in USB hub

- Security Key

What options are field upgradeable on the ZXP Series 9 printer?

Field upgradeable options include:

- ISO HiCo/LoCo magnetic stripe encoding

- MIFARE contactless and contact encoder combo

- Contact station for third party contact encoders

- UHF Gen 2 RFID encoding

- iClass contactless and contact encoder combo

- Prox reader and contact encoder combo

- 802.1 b/g and 1 GB Ethernet connectivity

- Barcode scanner

What connectivity options are available for the ZXP Series 9 printer?

The ZXP Series 9 comes standard with:

- USB 2.0 at launch

- 10/100 Ethernet-ready at launch with firmware upgrade available in future release

- 802.1 b/g wireless and 1 GB Ethernet available in future releases