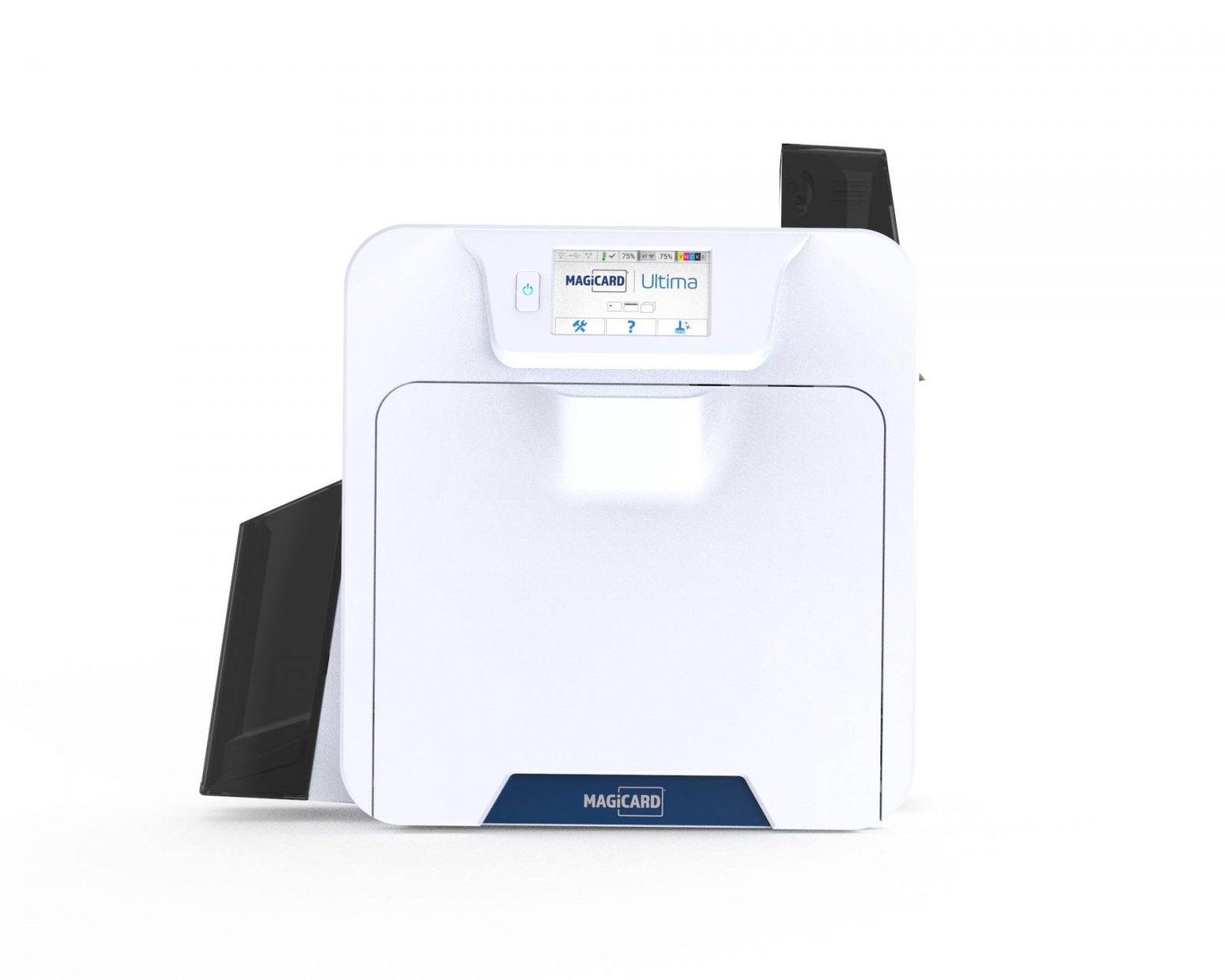

Printers

Retransfer Printing Technology

Retransfer Printing Technology Delivers the Optimal Card Printing Solution

The need for retransfer printing is real. A wide range of industries today are realising the significant benefits that personalised access control, financial, retail, and smart cards can bring to their enterprises. The rapid expansion of on-demand issuance of cards for identification, tracking, and monetary applications calls for an innovative card printing solution. However with an ever-increasing emphasis on security, flexibility, and efficiency, organisations now face the need to produce cards with the highest image quality, using a diverse range of card materials, with the broadest array of chip-encoding options.

Retransfer printing technology is the optimal on-demand printing solution for meeting the stringent image quality and encoding standards that the advanced card applications require. In the past, desktop retransfer printers offered low printing speeds and image quality, thus limiting their applicability in many card issuance applications. This lack of performance and quality slowed the adoption of retransfer technology industry-wide.Today, however, innovative technology for retransfer printing delivers a fast, flexible and affordable solution.

While direct-to-card (DTC) printing will continue to be the technology of choice for many standard card-printing applications, fast retransfer printing promises to expand a much broader range of possible applications, from high-security ID cards, to retail loyalty cards, to financial cards and beyond. In fact, retransfer technology offers a quantum leap beyond DTC printing. Retransfer printing commands 8 – 10% of the current market, with the current market expected to grow to 12 – 15% within three years. (based on a 2008 survey of select markets).

Retransfer Printing Delivers Key Advantages

Under the hood, retransfer technology uses a process called reverse thermal transfer. Unlike traditional dye sublimation card printers, which use a print head to transfer the image through a dye ribbon directly onto the card surface, retransfer printers use a two-step process:

1. The retransfer process prints a high-resolution image in reverse directly onto a clear receiving layer carried by a flexible, intermediate film. The dye sublimation process prints the image to the film, just like DTC printing.

2. The printer uses heat and pressure to thermally transfer the image and the entire image-receiving intermediate film onto the card surface. During this process, the layer thermally bonds to the card surface, and the printed image resides underneath the clear image-receiving layer, inside the card.

Superior Image Quality

When it comes to identification cards in demanding government and business applications, photo image quality is essential. security depends on photos that accurately portray the cardholder, and businesses expect sharp graphics and faithful reproduction of colours to communicate their brands effectively. With retransfer technology, the days of fuzzy photos and dull graphics become a thing of the past.

The challenges of printing directly to a hard plastic card surface fundamentally limits the image quality of the DTC process. The relatively small number of affordable, durable card materials that accept dyes limits the types of cards used, and limits the intensity of colours that DTC can reproduce. In addition, the DTC process depends of uniform, intimate contact between the printhead, the dye ribbon, and the card surface. Because of the unevenness of many card surfaces, DTC cannot achieve high colour intensity and uniformity when transferring dye directly to a card.

Retransfer printing separates the image creation step from the card application step, relieving many of the inherent constraints of DTC. The intermediate film is thin and flexible, making it easy to maintain uniform printing pressure. In addition, the retransfer process can optimise the dye for print quality – regardless of the card material. This ability to print first and then transfer to the card opens up new possibilities for high image quality.

Greater Flexibility

Identification cards and smart cards use a variety of materials in their production. Enterprises in the public and private sector demand flexibility when choosing cards that meet specific cost and application requirements. Built with a wide range of materials, smart cards contain circuitry such as a microprocessor and memory pre-loaded with information. In reality, DTC dye sublimation requires a porous surface, available only with PVC-based cards, this limiting card material options.

In many sophisticated plastic card applications, such as retail loyalty, smart cards, and finance, it is important to cover the card surface entirely with background graphics, yielding a more professional look. Traditional DTC printers leave a small white border around the outside perimeter of the card, due to the difficulty of maintaining contact all the way to the edges during printing. This white border detracts from the look of the card and discourages adoption for high-end applications.

Through over-the-edge printing. Retransfer technology enables true edge-to-edge images, giving users access to the entire card surface. Retransfer prints the image to the intermediate film in a slightly oversize form factor, so that the transfer to the card surface occurs with complete edge-to-edge coverage. This full “over-the-edge” effect produces a sleek, photo-like appearance that is very different from the traditional ID card.

The retransfer process is relatively insensitive to the card material, permitting the printing of high quality images on a wide variety of card types. In addition, retransfer enables “green” initiatives that require biodegradable cards. These advantages clearly differentiate the retransfer process from the DTC, and provide a significant advantage to many applications.

Improved Security and Tamper Resistance

With all forms of theft on the rise, government agencies and businesses must take every precaution to secure their workforce and assets. The transfer film inherently provides fraud protection since the film easily shows tamper evidence. Any attempt to tamper with data on the card also damages the film – which cannot be easily repaired or re-used. Users gain edge-to-edge protection of a security credential, with durability exceeding a comparable DTC print.

For added security, retransfer technology allows the use of transfer films with holographic images. In addition, users can use laminates with a multitude of security features such as holographic images, optical variable ink, and morphing for an even greater layer of security.

Lower Print Head Costs

In traditional DTC printers, the printheads must contact the rigid card substrates, creating excessive wear. When printing to the card edge, DTC printheads often suffer premature failure, or outright damage. Because retransfer printers print on soft transfer film panels, printhead life span improves dramatically. The result is a reduction in overheads for spare printheads, lowered maintenance workload, and significantly improved return on investment (ROI)

shop retransfer printers